Drip edge flashing is supposed to push water away from houses. It is the front line of defense for most horizontal planes in a building: top and bottom of a window, roof eave, balconies, base of wall, etc.

Because of water has a unique ability to stick to surfaces—like when you wash your hands, and then lift them from the sink, and the water runs down your arms to your elbows (instead of dropping straight from your hands). Because houses don't have elbows, people use geometry to kick water away from walls.

Drip edge /drip ej/ (noun)

"The leading edge of a flashing, sill, overhang or other linear, horizontal building element designed to shed water."

Without elbows, water flows over the surface of a house—the wall—until it hits the ground. And soaks into the basement. If the surface of the house is brick, then all of this water can have serious freeze/thaw implications. If it is wood, then there could be serious rot implications. If it is something else, then there are other implications.

So, can you trust drip edge to do its job?

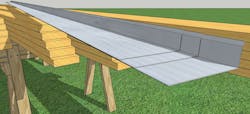

Jonathan Smegal is a senior researcher with RDH Building Science Laboratories and he wondered that too. So he built an apparatus to test it.

Smegal tested scenarios using different edge profiles, materials, and overhang distances.

Turns out, there are turncoats in the drip edge ranks: some profiles actually do more harm than good.

Key findings:

Sloped stone (8°) with a 3/4 inch overhang shed all of the water to the ground, directing none to the wall. The water moved slower and horizontally before driping neatly to the ground.

Jonathan's recommendations:

- Something is better than nothing. Less-than-ideal drip edges may still perform well, but they may potentially stain the cladding.

- Thicker is better, but don't hem it. One practical conclusion suggested by this study is that drip edge performance can be improved by increasing the thickness of the metal drip edge so that it does not require a hemmed edge. For example, it would be better to use 12 gauge without a hemmed edge, compared to a 20 gauge with a hemmed edge, especially when the overhang distance is small.

Read the original research paper:

- Effectiveness of Different Drip Edge Designs, Smegal, et al

About the Author

Dan Morrison

Dan Morrison is a founding editor of ProTradeCraft.com, where he is also the editor-in-chief. Fun fact: Dan is also a founding editor of Green Building Advisor and executive editor of Fine Homebuilding.